- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 132 Author: A-ZEN Academy Publish Time: 2022-04-16 Origin: Original

From A Fashion Chaser to A Fashion Creator-Creative ideas realized on HKS4-EL Tricot Machine

The tricot machine is designed to produce fabrics of generally simple design, but at a very high production rate. Our tricot machines are available in two different versions. Depending on the intended end-use and fabric construction, you can choose tricot machine HKS3M and Tricot machine HKS4.

As a high-speed tricot machine with 4 guide bars and electrical drive systems, HKS4-EL gained a great success when it enters the market.

In 2020, A-ZEN HKS4-EL tricot warp knitting machines of 290” width were developed to produce bubble elastic fabrics, which were one of the most fashionable fabrics then.

The daily productivity of nearly 900kg per day (24 hours), the massive productivity makes the 290” wide HKS4-EL a tremendous reputation in the markets.

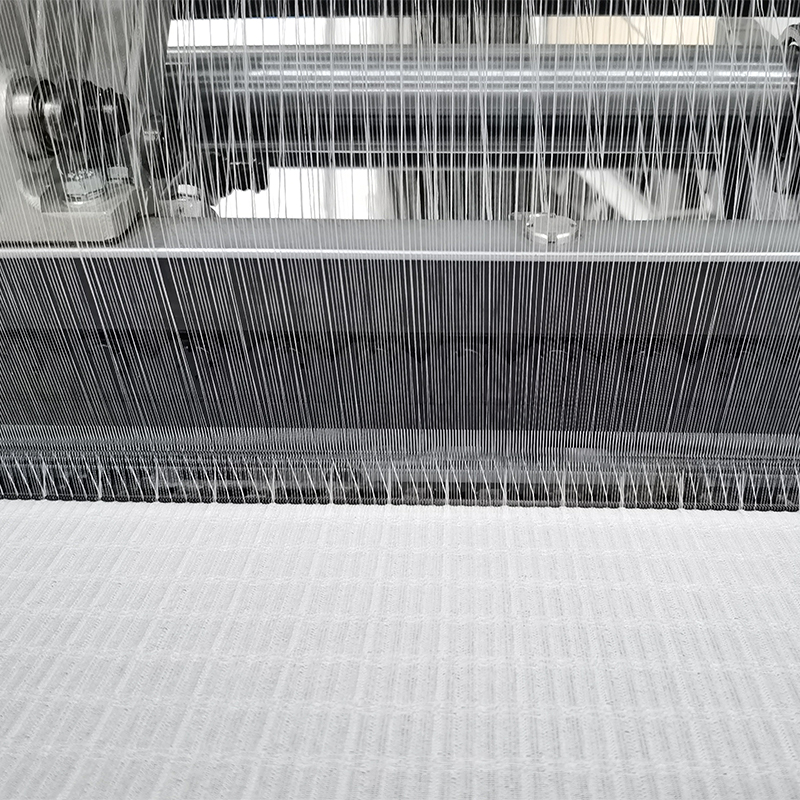

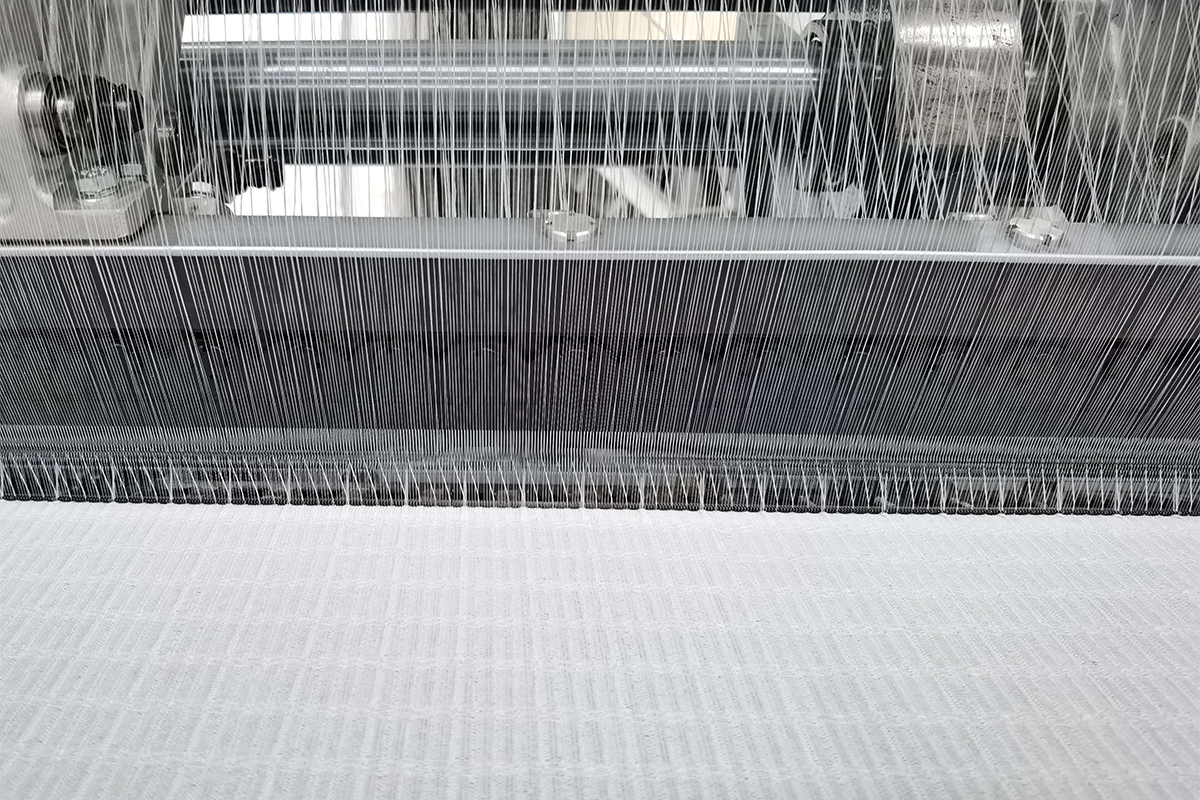

Bubble Fabrics

bubble fabrics by HKS4EL

HKS4-EL tricot machine, E28, 290” wide machine equipped with carbon fiber needle beds, and guide bars, the EL drive system is from Yaskawa (Japan), and compound needle elements are from Groz-Beckert, while guide needles, tongue needle, and sinkers are from Saxonia.

Thanks to the stable working spare parts, HKS4-EL could work at 1200-1700rpm.

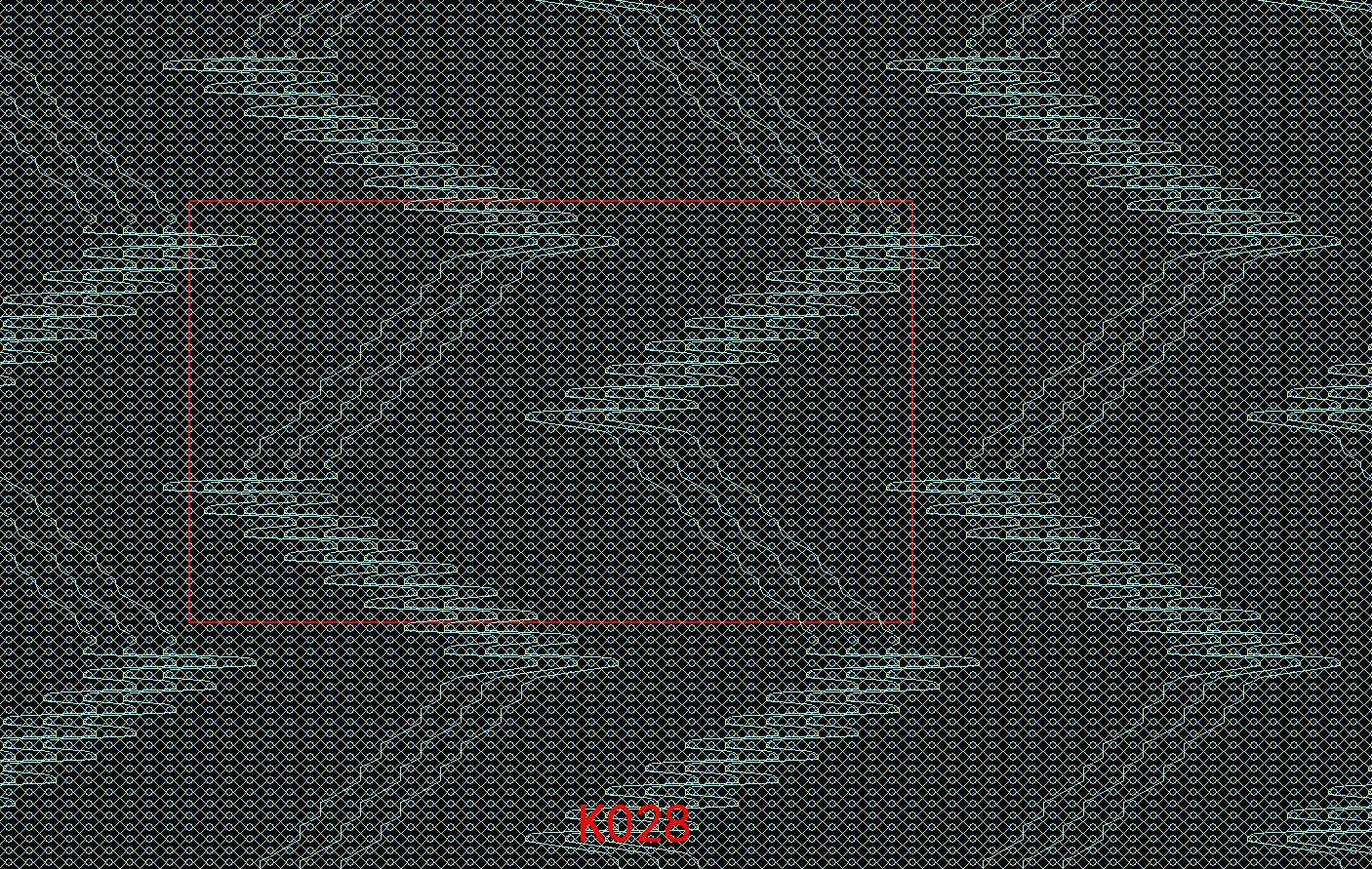

Four Bars and Needle Beds are made from Carbon Fiber Material

Meantime, we also develop some bubble designs for our customers, any customer who requests bubble textile designs could reach us by sending an email to: info@azentex.com

GB1: 1- 0/ 1- 2//

GB2: 1- 2/ 1- 0//

GB3: 5- 5/ 6- 6/ 7- 7/ 7- 7/ 8- 8/ 8- 8/ 9- 9/10-10/10-10/11-11/11-11/12-12/13-13/

13-13/14-14/14-14/15-15/19-19/14-14/17-17/12-12/15-15/10-10/13-13/8-8/11-11/6- 6/ 9- 9/ 4- 4/ 7- 7/ 2- 2/ 5- 5/ 0- 0/ 5- 5/ 4- 4/ 5- 5//

GB4: 4- 4/ 9- 9/ 6- 6/11-11/ 8- 8/13-13/10-10/15-15/12-12/17-17/14-14/19-19/14-14/

15-15/14-14/14-14/13-13/12-12/12-12/11-11/11-11/10-10/ 9- 9/ 9- 9/ 8- 8/ 8- 8/

7- 7/ 6- 6/ 6- 6/ 5- 5/ 5- 5/ 4- 4/ 0- 0/ 5- 5/ 2- 2/ 7- 7//

Related Resource: Tricot Machine Catalog