- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

RDJ5/1. RDJ6/1, RDJ7/1

A-ZEN

138“

E22, E24, E28

| Availability: | |

|---|---|

| Quantity: | |

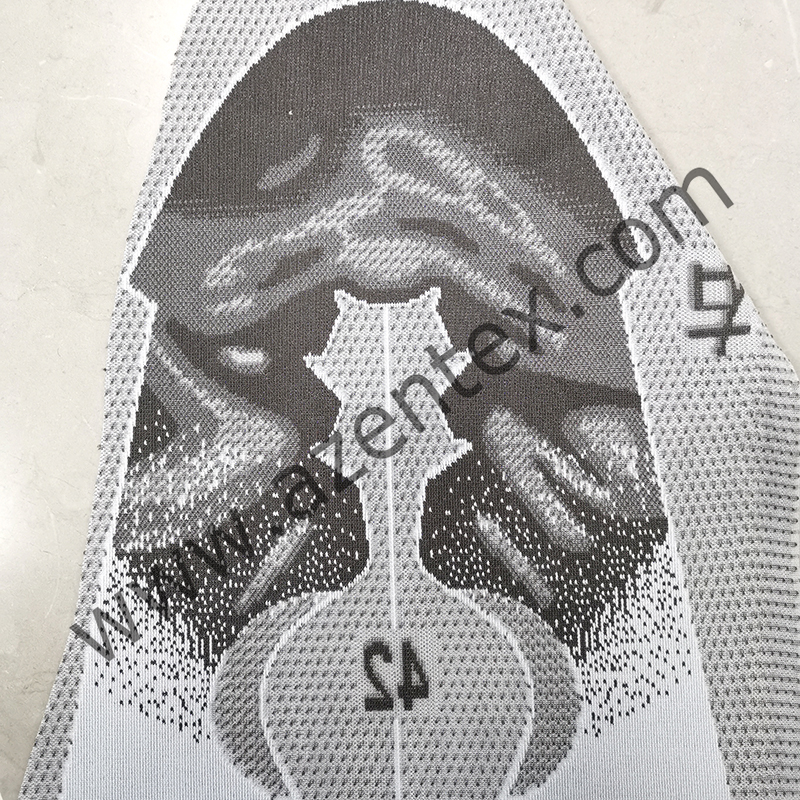

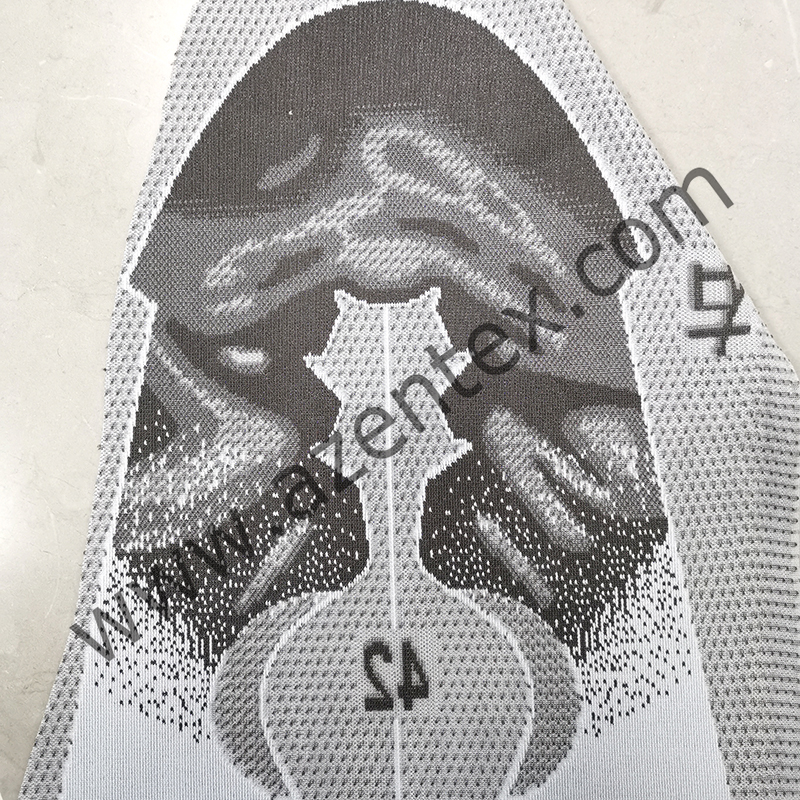

Jacquard double needle bar raschel machine refers to the double-bar raschel machines with the piezo jacquard technology, which is capable of making patterns on the surface of shoe uppers (Technical Article: How to Make Designs for Warp Knitting Jacquard Shoes?) and patterned mattress spacer.

piezo jacquard technology, which is capable of making patterns on the surface of shoe uppers (Technical Article: How to Make Designs for Warp Knitting Jacquard Shoes?) and patterned mattress spacer.

double needle bar warp knitting machine RDJ5/1, RDJ6/1, and RDJ7/1 are for producing patterned spacer textiles, while RDJ4/2 and RDJ6/2 are for producing seamless dresses, pantyhose leggings, and belts.

A-ZEN RDJ type double needle bar jacquard warp knitting machine is a professional shoe upper fabric knitting machine. With 4 or 5 ground guide bars and separate piezo-jacquard bar, various mesh nets are achievable. Besides, the stable working performance ensures a large productivity.

More to read: https://www.azentex.com/how-to-produce-superior-warp-knitted-shoe-upper-fabric.html

1. Working Width/Gauge: 138"/E22, E24, E28;

2. Working Speed: 50-550rpm (Depends on Yarn and Designs);

3. Knock-over Comb Bar Distance: 2-12mm;

4. Bars/Knitting Elements: 2 needle bars with latch needle units (individual needle and needle block optional), 2 knock-over comb bars;

5. Pattern Drive System: EL Drive;

6. Yarn Let-off Device: EBC Yarn Let-off System;

7. Fabric Take-up: Electronical Fabric Take-up System;

8. Batching Device: Electronical Batching Device;

9. Laser Stop Detector and Online Service Program Equipped;

10. Air Blower Device: Optional.

1. Stable Working Performance;

2. Reliable Spare-parts Partners

(1) Needle Elements Suppliers: Groz-Beckert, Saxonia;

(2) EL Drives Suppliers: Mitsubishi, Nidec, Yaskawa;

(3) Bearing Suppliers: NSK, INA, FAG;

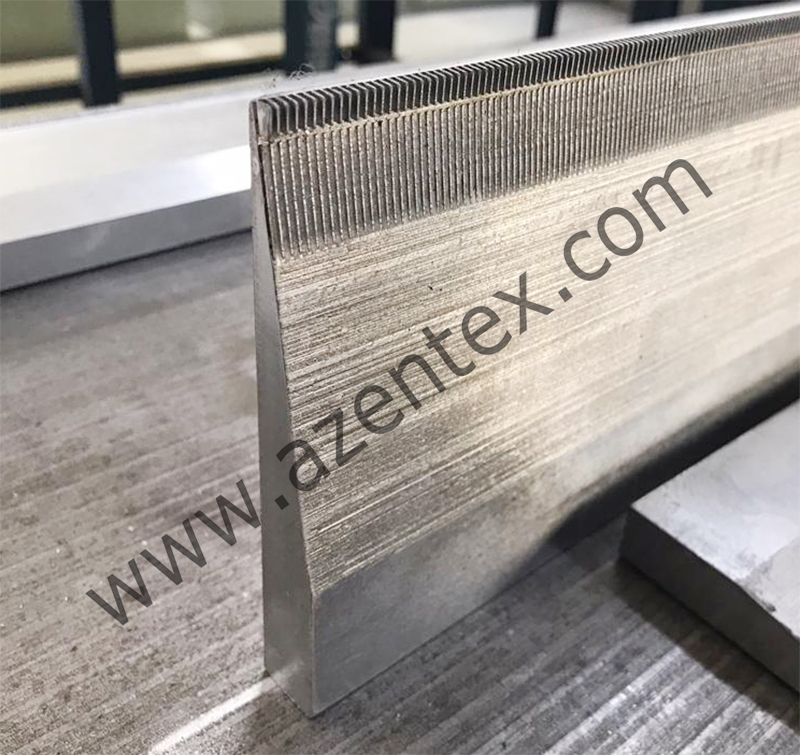

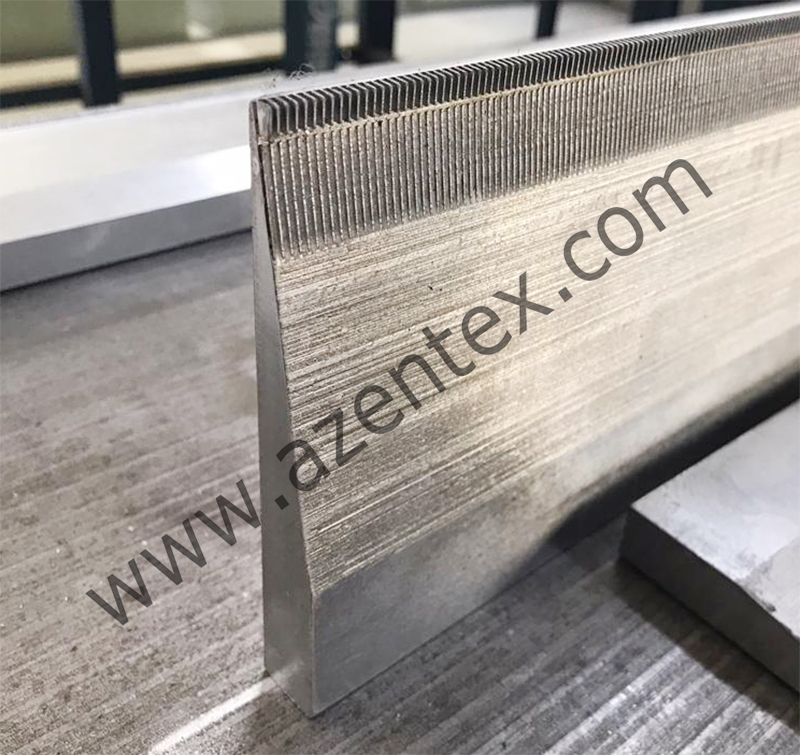

(4) Needle Beds and Bars Material: Magnalium Material;

(5) Electrical Elements Suppliers: Schneider, Siemens, Omron, INVT;

(6) Take-up Belt: Bobotex.

3. Overseas Service Team: Türkiye, India, Egypt, Indonesia, Pakistan, and Iran.

Individual latch needles

lacth needles blocks (Optional)

Piezo Jacquard (Saxonia needle pins)

High-quality knock-over comb bar

Full ground bars driven by EL motors

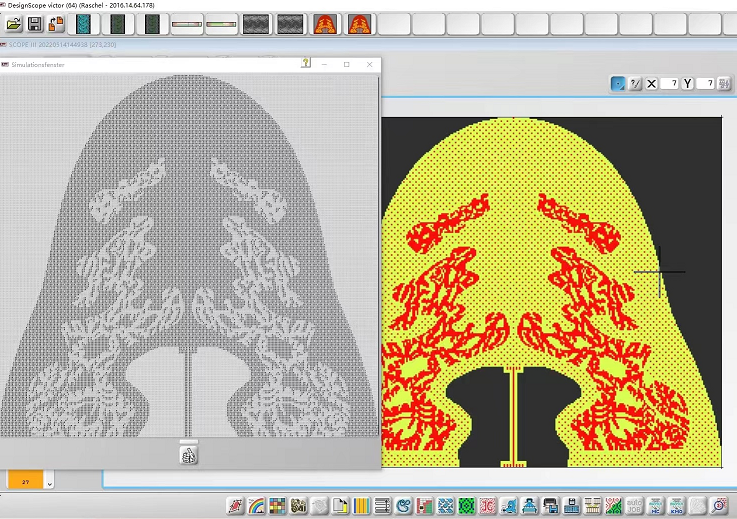

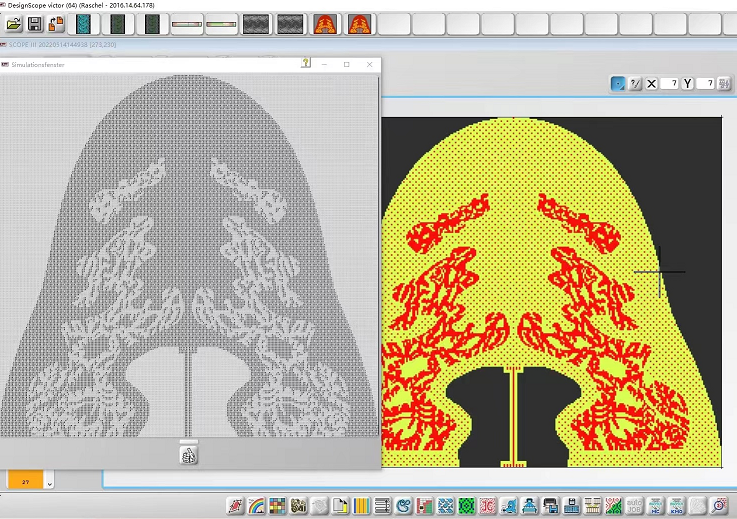

Design simulation effect on warp knitting design program.

Warp Knitting Machine Delivery

Seaworthy Package

The local service team in Turkey, Egypt, India, Pakistan, Indonesia

In-time online service

Detailed operation manual

Machine in-house test before delivery

CHANGZHOU A-ZEN TEXTILE TECHNOLOGY CO LTD. is a warp knitting machines and spare parts manufacturer, which locates in Changzhou, China. In the past 15 years, we have already provided nearly 1,000 sets of warp knitting machinery in markets, including Multi-bar Raschel machines, Jacquard Machines, Tricot Machines, Double-Needle Bars Machines, and Warping Machines.

Driven by a responsible attitude, ongoing innovation, and open collaboration, A-ZEN has established a competitive warp knitting technology (WKT) portfolio of end-to-end solutions in warp knitting machinery, spare parts, and technology training, and the markets including China, Turkey, India, Egypt, Indonesia, Bangladesh, Brazil, Pakistan, Syria, Iran, Kenya, Thailand, Mexico, and other countries and areas.

Thanks to the sound technology and in-time after-sales service, A-ZEN has won a high reputation from markets, and A-ZEN is committed to enabling the warp knitting future diversified industry and building a better world.

Manufacturing Factories:

We have four workshops, two of them are warp knitting machines and warping machines workshops, and another two are fabric production mill and spare parts manufacture workshops separately.

Most of our newly developed machines will be used in our fabric knitting factory for a profound test, after which, we will promote them into the market.

Spare parts such as compound needle bed, tongue needle bed, needle guide bar, sinker bed, and latch needle bed is produced in our CNC machines, the bars or beds used on Chinese and German warp knitting machines.

Global Exhibition:

Global Exhibition: We attend professional textile machinery exhibitions worldwide, such as ITMA, ITM, ITME, and many others. During the exhibition, we not only display our newly developed technology but also offer economical products to our customers.

It is also a good time to collect customers' feedback and new demand so that we could make better machines for them.

Commuication and Cooperation is our theme to participate in all exhibitions.

Customer Training

Customer Training Technical support plays an extremely role in warp knitting machine services. We offer different forms of training, including professional manual books, online guides, video albums, and on-site training.

So far, we have offered on-site training in more than 10 countries and built up our own local service teams in Turkey, India, Pakistan, Indonesia, Iran, and Egypt.

Our in-time & professional technical support gain a high reputation in markets.

A: We are a manufacturer since 2012, and we have our own trading company in 2017, the brand of which is A-ZEN, which is specialized in importing and exporting services.

A: We provide local service in India, Turkey, Egypt, Indonesia, Pakistan, and Iran so far, and we will enlarge our service teams in more countries in the near future.

A: Before machine delivery, we have an in-house test process, to make sure the machine performs perfectly. After the machine arrives, we provide an in-time online guide to support our customers finish the machine installation.

A: Firstly, we produce and provide lots of machines to the market, and our machines' lifespan and quality ensured by different markets over the years.

Secondly, we largely use renowned and market-tested spare-part brands, to make sure the mechnical and electrical parts are durable.

Besides, we have regular service to customers, to check the quality of our machines and remind customers of maintenance, so our customers could run machine always in stable performance.

Jacquard double needle bar raschel machine refers to the double-bar raschel machines with the piezo jacquard technology, which is capable of making patterns on the surface of shoe uppers (Technical Article: How to Make Designs for Warp Knitting Jacquard Shoes?) and patterned mattress spacer.

piezo jacquard technology, which is capable of making patterns on the surface of shoe uppers (Technical Article: How to Make Designs for Warp Knitting Jacquard Shoes?) and patterned mattress spacer.

double needle bar warp knitting machine RDJ5/1, RDJ6/1, and RDJ7/1 are for producing patterned spacer textiles, while RDJ4/2 and RDJ6/2 are for producing seamless dresses, pantyhose leggings, and belts.

A-ZEN RDJ type double needle bar jacquard warp knitting machine is a professional shoe upper fabric knitting machine. With 4 or 5 ground guide bars and separate piezo-jacquard bar, various mesh nets are achievable. Besides, the stable working performance ensures a large productivity.

More to read: https://www.azentex.com/how-to-produce-superior-warp-knitted-shoe-upper-fabric.html

1. Working Width/Gauge: 138"/E22, E24, E28;

2. Working Speed: 50-550rpm (Depends on Yarn and Designs);

3. Knock-over Comb Bar Distance: 2-12mm;

4. Bars/Knitting Elements: 2 needle bars with latch needle units (individual needle and needle block optional), 2 knock-over comb bars;

5. Pattern Drive System: EL Drive;

6. Yarn Let-off Device: EBC Yarn Let-off System;

7. Fabric Take-up: Electronical Fabric Take-up System;

8. Batching Device: Electronical Batching Device;

9. Laser Stop Detector and Online Service Program Equipped;

10. Air Blower Device: Optional.

1. Stable Working Performance;

2. Reliable Spare-parts Partners

(1) Needle Elements Suppliers: Groz-Beckert, Saxonia;

(2) EL Drives Suppliers: Mitsubishi, Nidec, Yaskawa;

(3) Bearing Suppliers: NSK, INA, FAG;

(4) Needle Beds and Bars Material: Magnalium Material;

(5) Electrical Elements Suppliers: Schneider, Siemens, Omron, INVT;

(6) Take-up Belt: Bobotex.

3. Overseas Service Team: Türkiye, India, Egypt, Indonesia, Pakistan, and Iran.

Individual latch needles

lacth needles blocks (Optional)

Piezo Jacquard (Saxonia needle pins)

High-quality knock-over comb bar

Full ground bars driven by EL motors

Design simulation effect on warp knitting design program.

Warp Knitting Machine Delivery

Seaworthy Package

The local service team in Turkey, Egypt, India, Pakistan, Indonesia

In-time online service

Detailed operation manual

Machine in-house test before delivery

CHANGZHOU A-ZEN TEXTILE TECHNOLOGY CO LTD. is a warp knitting machines and spare parts manufacturer, which locates in Changzhou, China. In the past 15 years, we have already provided nearly 1,000 sets of warp knitting machinery in markets, including Multi-bar Raschel machines, Jacquard Machines, Tricot Machines, Double-Needle Bars Machines, and Warping Machines.

Driven by a responsible attitude, ongoing innovation, and open collaboration, A-ZEN has established a competitive warp knitting technology (WKT) portfolio of end-to-end solutions in warp knitting machinery, spare parts, and technology training, and the markets including China, Turkey, India, Egypt, Indonesia, Bangladesh, Brazil, Pakistan, Syria, Iran, Kenya, Thailand, Mexico, and other countries and areas.

Thanks to the sound technology and in-time after-sales service, A-ZEN has won a high reputation from markets, and A-ZEN is committed to enabling the warp knitting future diversified industry and building a better world.

Manufacturing Factories:

We have four workshops, two of them are warp knitting machines and warping machines workshops, and another two are fabric production mill and spare parts manufacture workshops separately.

Most of our newly developed machines will be used in our fabric knitting factory for a profound test, after which, we will promote them into the market.

Spare parts such as compound needle bed, tongue needle bed, needle guide bar, sinker bed, and latch needle bed is produced in our CNC machines, the bars or beds used on Chinese and German warp knitting machines.

Global Exhibition:

Global Exhibition: We attend professional textile machinery exhibitions worldwide, such as ITMA, ITM, ITME, and many others. During the exhibition, we not only display our newly developed technology but also offer economical products to our customers.

It is also a good time to collect customers' feedback and new demand so that we could make better machines for them.

Commuication and Cooperation is our theme to participate in all exhibitions.

Customer Training

Customer Training Technical support plays an extremely role in warp knitting machine services. We offer different forms of training, including professional manual books, online guides, video albums, and on-site training.

So far, we have offered on-site training in more than 10 countries and built up our own local service teams in Turkey, India, Pakistan, Indonesia, Iran, and Egypt.

Our in-time & professional technical support gain a high reputation in markets.

A: We are a manufacturer since 2012, and we have our own trading company in 2017, the brand of which is A-ZEN, which is specialized in importing and exporting services.

A: We provide local service in India, Turkey, Egypt, Indonesia, Pakistan, and Iran so far, and we will enlarge our service teams in more countries in the near future.

A: Before machine delivery, we have an in-house test process, to make sure the machine performs perfectly. After the machine arrives, we provide an in-time online guide to support our customers finish the machine installation.

A: Firstly, we produce and provide lots of machines to the market, and our machines' lifespan and quality ensured by different markets over the years.

Secondly, we largely use renowned and market-tested spare-part brands, to make sure the mechnical and electrical parts are durable.

Besides, we have regular service to customers, to check the quality of our machines and remind customers of maintenance, so our customers could run machine always in stable performance.